INTRODUCING MACHINESAFE

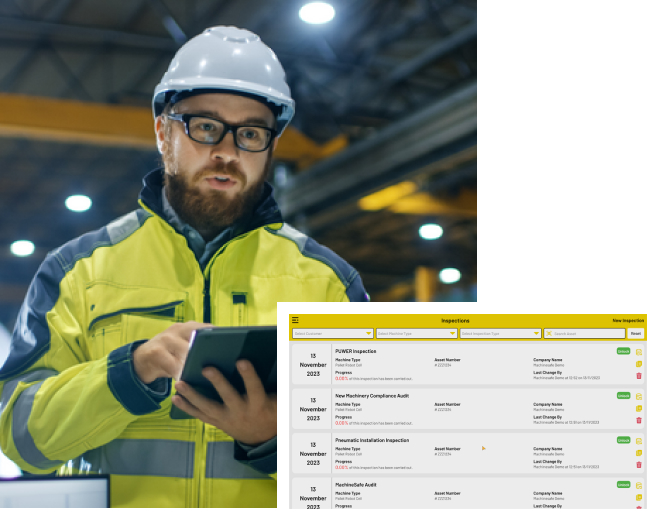

Streamline safety and compliance inspections with ease using our MachineSafe Compliance software platform. Developed by in-house safety experts, it simplifies the process, offering an intuitive design for efficient inspections. Save time and complexity, making it a seamless experience for users on the web or Android/iPad tablets.

Safe and secure Cloud syncing to the MachineSafe portal, where inspections are securely stored. Synced inspections can be edited and distributed.

Risk assessments integrated into inspection modules to seamlessly record non-compliance items during inspections.

Comprehensive PUWER training and support packages to help maximize your MachineSafe potential and increase your company's competencies.

A wide range of inspection modules, including PUWER, Risk Assessments, New Machinery Assessment, CE/UKCA Marking and pneumatic and hydraulic systems. Customer's can also add their own inspection templates for inhouse use.

Full collaboration between company users, as well as the ability to share clear PDF reports with your customers via our free-to-use viewer portal access for full transparency.

Our intuitive app interface is designed to remove the burden of carrying out inspections, simplifying the inspection process thus allowing the assessor to concentrate on the inspection in hand.

Carry out offline inspections and audits from an iPad or Android tablet.

Inspections synced to the Cloud for secure storage

Search, edit & update reports and inspections.

Forward reports to colleagues and customers.

Carry out offline inspections and audits from an iPad or Android tablet.

Inspections synced to the Cloud for secure storage

Search, edit & update reports and inspections.

Forward reports to colleagues and customers.

FAQs provide concise answers to common queries, streamlining information for users' convenience. They serve as a valuable resource.

We recommend using Microsoft Edge

Our team uses Lenovo Andriod tablets

We accept the following: Company PO's, Bank Transfer & Credit Cards.

Your MachineSafe subscription will be enabled as soon as we receive your Company PO or Payment

You can email: support@machinesafe.co.uk or call our support number: 01793 547018. We offer support contracts.

In short, No. MachineSafe is a subscritpion service. However, we do offer the 12 month free for companies who pay annually

You need to be computer literate, however MachineSafe does not remove the requirement to be competent to complete the inspection to be carried out.

Yes, we offer training such as PUWER. Training can be carried out on or off-site

Suite 2. Basepoint Business Centre.

Swindon. SN5 7EX. UK

+44 (0)1793 547018

info@machinesafe.co.uk

Subscribe to our safety newsletter for the latest safety news and changes to legislation.